Fill in a Valid Welder Performance Qualification Record Form

Common PDF Forms

Living Will Registry - This form empowers individuals to make informed healthcare decisions.

To facilitate the process of transferring ownership, it's crucial to have a clear understanding of the New York Mobile Home Bill of Sale form, which can be found on platforms like OnlineLawDocs.com. This document not only confirms the details of the transaction but also protects both the buyer and seller by providing legal acknowledgment of the sale.

What Is a Bol - The Bill of Lading and its supplement should be securely stored for record-keeping.

Misconceptions

Misconceptions about the Welder Performance Qualification Record (WPQR) form can lead to confusion and errors in the qualification process. Here are five common misconceptions:

- The WPQR is only for certified welders. Many believe that only certified welders need to complete this form. In reality, it applies to all welders and welding operators, regardless of certification status. The record serves as a formal documentation of their skills and qualifications.

- Completing the WPQR guarantees employment. Some think that filling out the WPQR will automatically secure a job. However, while it demonstrates qualifications, employment decisions depend on various factors, including company needs and other applicants' qualifications.

- The WPQR is a one-time requirement. Many assume that once the WPQR is completed, it does not need to be updated. This is incorrect. Welders must update their records whenever they change processes, materials, or positions to ensure their qualifications remain valid.

- All sections of the WPQR must be filled out. Some believe that every section of the form is essential. However, certain variables may be marked as non-essential, and it is acceptable to indicate "NA" for those sections as specified by the relevant code or specification.

- The WPQR is only for structural welding. There is a misconception that the WPQR is limited to structural welding. In fact, it applies to various types of welding, including pipe welding and other specialized processes, depending on the specifications used.

Documents used along the form

The Welder Performance Qualification Record (WPQR) is a vital document in the welding industry, serving as a testament to a welder's skills and qualifications. However, it is often accompanied by several other forms and documents that provide additional context, verification, and compliance. Understanding these related documents can enhance the overall qualification process and ensure adherence to industry standards.

- Welding Procedure Specification (WPS): This document outlines the specific procedures and parameters that must be followed during the welding process. It includes details such as the type of materials, welding techniques, and environmental conditions. The WPS serves as a guideline to ensure consistency and quality in welding operations.

- Procedure Qualification Record (PQR): The PQR is a record that demonstrates the welding procedure's ability to produce a sound weld. It includes the results of tests performed on welds made according to the WPS. This document helps verify that the welding procedure meets the necessary mechanical and structural requirements.

- Test Reports: These reports document the results of various tests conducted on the welded joints. They may include mechanical testing, such as tensile and impact tests, as well as non-destructive testing (NDT) results. Test reports provide evidence of the weld quality and help ensure compliance with industry standards.

- Welder Certification: This document certifies that the welder has successfully completed the necessary training and testing to perform specific welding tasks. It often includes information about the types of welding processes the individual is qualified to perform and the corresponding codes or standards.

- Dog Bill of Sale: The All California Forms is crucial for both buyers and sellers, acting as legal proof of the transaction and ensuring the formal transfer of ownership for canines in the state.

- Inspection Reports: These reports are generated by qualified inspectors who evaluate the welding work for compliance with the relevant codes and standards. Inspection reports often include findings from visual inspections, as well as results from any non-destructive testing performed on the welds.

Collectively, these documents work in harmony with the Welder Performance Qualification Record to ensure that welders meet industry standards and maintain high levels of workmanship. Together, they form a comprehensive framework that supports quality assurance and safety in welding practices.

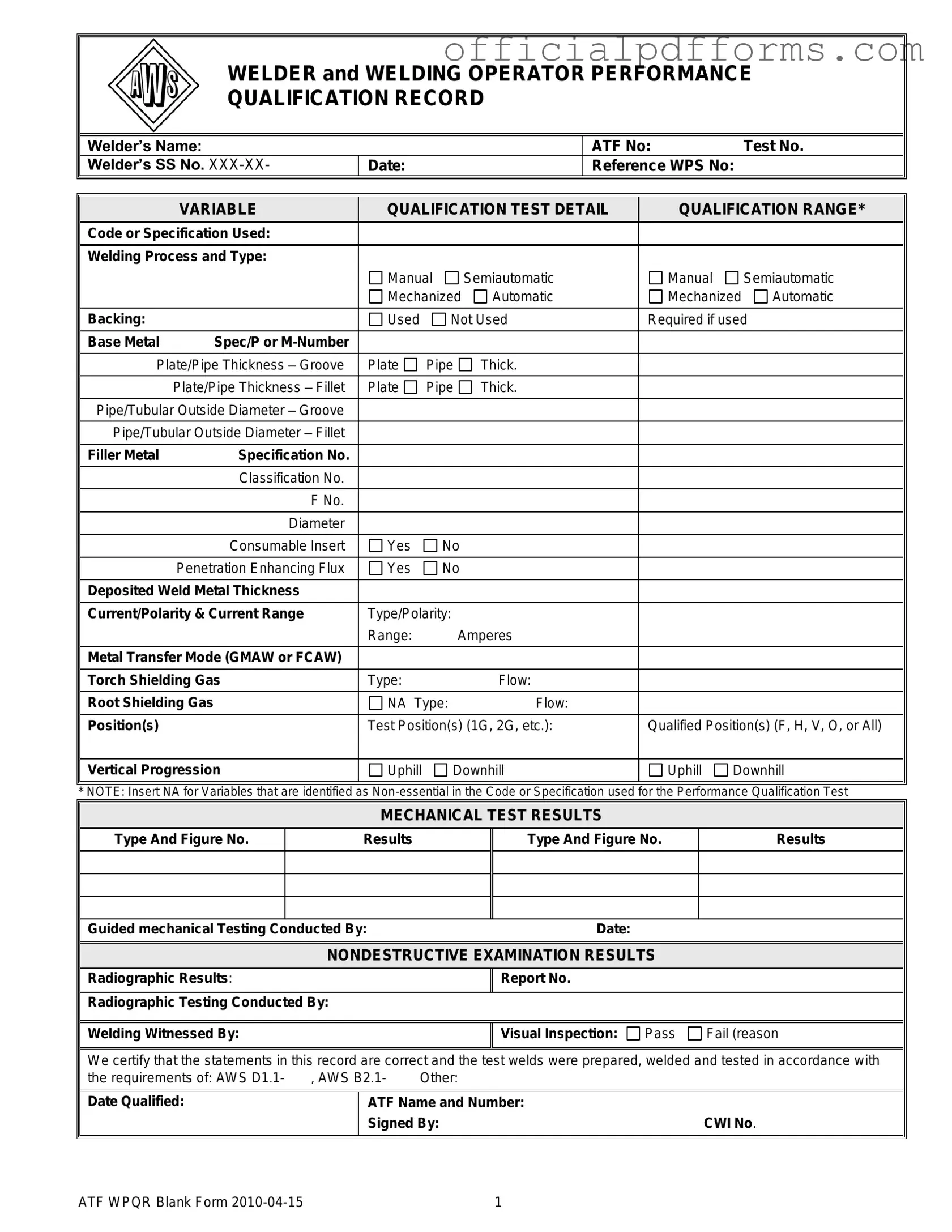

Steps to Filling Out Welder Performance Qualification Record

Filling out the Welder Performance Qualification Record form is an essential step in documenting a welder's qualifications. This form helps ensure that all necessary information is captured accurately for compliance and record-keeping. Follow these steps to complete the form correctly.

- Welder's Name: Enter the full name of the welder.

- ATF No: Input the appropriate ATF number.

- Test No: Fill in the test number assigned to this qualification.

- Welder's SS No: Provide the Social Security Number of the welder.

- Date: Write the date when the qualification test was conducted.

- Reference WPS No: Enter the Welding Procedure Specification number.

- Code or Specification Used: Specify the code or specification that applies to the qualification.

- Welding Process and Type: Indicate the welding process and type (e.g., Manual, Semiautomatic, Mechanized, Automatic).

- Backing: Note whether backing was used or not.

- Base Metal Spec/P or M-Number: Fill in the specification or material number for the base metal.

- Plate/Pipe Thickness: Record the thickness for groove and fillet welds.

- Pipe/Tubular Outside Diameter: Provide the outside diameter for groove and fillet welds.

- Filler Metal Specification No: Enter the specification number for the filler metal.

- Classification No: Write the classification number for the filler metal.

- F No.: Fill in the F number associated with the filler metal.

- Diameter: Specify the diameter of the filler metal.

- Consumable Insert: Indicate if a consumable insert was used.

- PENETRATION ENHANCING FLUX: Note whether penetration enhancing flux was used.

- Deposited Weld Metal Thickness: Record the thickness of the deposited weld metal.

- Current/Polarity & Current Range: Specify the type of current and its range in amperes.

- Metal Transfer Mode: Indicate the mode of metal transfer (e.g., GMAW or FCAW).

- Torch Shielding Gas Type: Fill in the type of shielding gas used and its flow rate.

- Root Shielding Gas: If applicable, specify the type and flow of root shielding gas.

- Test Position(s): Enter the test positions (e.g., 1G, 2G, etc.).

- Qualified Position(s): Note the qualified positions (e.g., F, H, V, O, or All).

- Vertical Progression: Indicate the progression method (Uphill or Downhill).

- MECHANICAL TEST RESULTS: Provide details on the type and results of mechanical tests conducted.

- Guided Mechanical Testing Conducted By: Name the person or entity that conducted the testing.

- Date: Fill in the date when the mechanical testing was conducted.

- NONDESTRUCTIVE EXAMINATION RESULTS: Document the results of any radiographic testing and provide the report number.

- Radiographic Testing Conducted By: Name the individual or organization that performed the radiographic testing.

- Welding Witnessed By: List the name of the person who witnessed the welding.

- Visual Inspection: Note the results of the visual inspection (Pass or Fail) and provide a reason if it failed.

- Certification: Certify that the statements in the record are correct and fill in the date qualified.

- ATF Name and Number: Write the name and number of the ATF.

- Signed By: Include the signature of the individual certifying the record.

- CWI No: Enter the number of the Certified Welding Inspector.

Common mistakes

-

Incomplete Personal Information: Failing to provide all required personal details, such as the welder’s name, Social Security number, and ATF number, can lead to delays or invalidation of the record.

-

Incorrect Test Number: Entering the wrong test number can create confusion and make it difficult to trace the qualification back to the specific tests conducted.

-

Omitting Reference WPS Number: Not including the Welding Procedure Specification (WPS) number may result in a lack of clarity regarding the procedures followed during the qualification.

-

Improper Selection of Welding Process: Selecting the wrong welding process or type can invalidate the qualification, as different processes have different requirements.

-

Neglecting Base Metal Specifications: Failing to accurately specify the base metal’s specifications or thickness can lead to issues with compliance and performance.

-

Missing Mechanical Test Results: Not providing results from mechanical tests can raise questions about the quality and reliability of the welds performed.

-

Inaccurate Non-Destructive Examination Results: Reporting incorrect results from non-destructive examinations can misrepresent the quality of the welds, leading to serious implications.

-

Failure to Obtain Required Signatures: Not securing the necessary signatures from qualified personnel can render the qualification record incomplete and unenforceable.

Get Clarifications on Welder Performance Qualification Record

What is the purpose of the Welder Performance Qualification Record (WPQR)?

The Welder Performance Qualification Record serves as a formal documentation of a welder's skills and capabilities. It verifies that the welder has successfully completed tests according to specific codes and standards, demonstrating their ability to produce quality welds in various conditions. This record is essential for employers and regulatory bodies to ensure compliance with industry standards.

Who needs to complete a WPQR?

Any welder or welding operator who wishes to validate their skills and qualifications must complete a WPQR. This includes individuals working in various industries such as construction, manufacturing, and repair. Employers may also require this documentation to ensure that their workforce meets the necessary qualifications for specific projects.

What information is included in the WPQR?

The WPQR contains several critical pieces of information, including:

- Welder's name and identification numbers

- Details about the welding process and materials used

- Test results, including mechanical and non-destructive examination outcomes

- Certification and signatures from qualified inspectors

This comprehensive information helps to establish the welder's qualifications and the conditions under which they were tested.

How is the WPQR validated?

The WPQR is validated through a series of tests that the welder must successfully complete. These tests are conducted by certified personnel and may include both mechanical testing and non-destructive examination. The results are recorded in the WPQR, and the document must be signed by a Certified Welding Inspector (CWI) to confirm its accuracy and compliance with applicable standards.

What types of welding processes are covered by the WPQR?

The WPQR covers various welding processes, including:

- Manual

- Semi-automatic

- Mechanized

- Automatic

Each of these processes may have specific requirements and qualifications that must be documented in the WPQR.

What are the qualifications for different welding positions?

Welding positions are categorized based on the orientation of the weld joint. Common positions include:

- Flat (1G)

- Horizontal (2G)

- Vertical (3G)

- Overhead (4G)

Each position requires specific skills, and the WPQR will indicate which positions the welder is qualified to perform.

What is the significance of non-destructive examination results in the WPQR?

Non-destructive examination (NDE) results are crucial as they assess the quality and integrity of the welds without damaging them. Common NDE methods include radiographic testing and visual inspection. A pass or fail result in these examinations can significantly impact the validity of the WPQR and the welder's qualifications.

How long is a WPQR valid?

The validity of a WPQR can vary depending on the specific industry standards and regulations. Generally, a WPQR remains valid as long as the welder continues to work in the field and maintains their skills. However, periodic requalification may be required, especially if there is a significant gap in welding activity or if the welder changes processes or materials.

Where can I find a WPQR form?

WPQR forms can typically be obtained from industry associations, training organizations, or directly from the companies that require them. Many organizations also provide downloadable templates online. Ensure that the form you use complies with the relevant codes and standards for your specific industry.